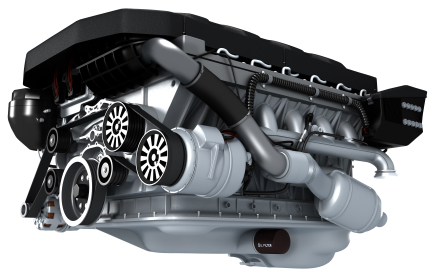

When you buy a new car with a fresh odometer, there are a few thing to keep in your mind. One of them is the fact that the first couple hundred miles of your car’s engine is very important on your engine’s overall life.

What is the proper engine break in procedure? The main goal of breaking in an engine is to wear out the piston rings in your engine just enough so that the rings fit into the cylinder walls perfectly.

A good fit will allow for an engine to achieve a better power (efficient combustion of gasoline) while consuming less oil. A more efficient combustion is also good for the environment as an efficient combustion leaves behind no atmospheric pollutants like carbon monoxide.

How to Do It

Opinions on a proper engine break in procedure differ amongst experts. However, the most accepted method is “cross-hatching,” a process that is designed to wear out the piston rings by roughening up the cylinder walls. To do this: first, roughen up the sides of your cylinder walls by using a metal file of a sort. Be careful to be thorough all around the circular walls, while not making any deep scratches. If you file too deep, you can end up making a hole between the different cylinders—this results in a broken engine.

The additional friction created by the roughened surface will wear down the piston rings, which causes bits of piston rings to stick in place of the roughened gaps. This provides a better fit between the piston and the ring, leading to a more efficient combustion.

Consult a Professional

Different cars have different engines and a particular type of engine break-in may not be suitable for your specific car. Consult your local professionals and give them information about your car before you attempt to make any changes to your engine.

TalkLocal can help with finding the correct local experts to help you in this case, saving you time and energy in what may be a stressful situation.